- info@deltaone.in

- +91 98840 09696

Semi Metallic Gaskets

Spiral Wound Gaskets

DELTAONE Spiral Wound gaskets are available in a variety of styles to suit the particular flange facing being utilized on the flanges.

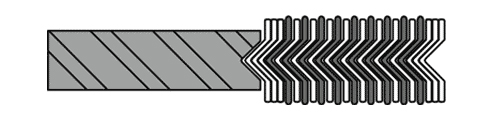

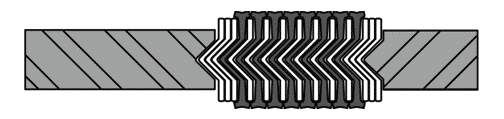

DELTAONE Style SW

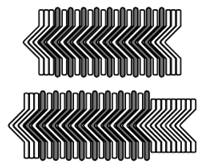

A winding is made of alternate plies of a metal wire and a soft non-metallic filler. The metal wire in the gasket is preformed into a "chevron" configuration, allowing superior resiliency and self-adjustment when compared to conventional gaskets. The Style W is just a sealing component (winding) only, which is normally used on tongue and groove joints, male and female facings and groove to flat flange facings.

A winding is made of alternate plies of a metal wire and a soft non-metallic filler. The metal wire in the gasket is preformed into a "chevron" configuration, allowing superior resiliency and self-adjustment when compared to conventional gaskets. The Style W is just a sealing component (winding) only, which is normally used on tongue and groove joints, male and female facings and groove to flat flange facings.

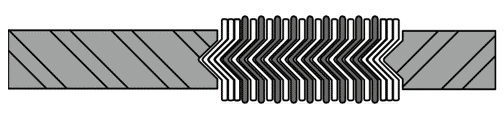

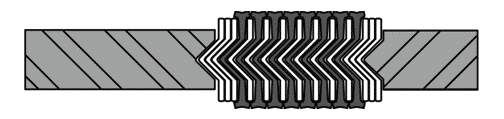

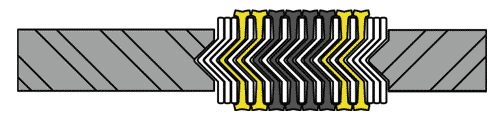

DELTAONE Style SWR

Style WR gaskets consist of a winding with a solid metal outer guide ring. These gaskets can be used on plain flat face flanges and on raised face flanges. The outer guide ring serves to center the gasket properly in the flange joint, acts as an anti-blowout device, provides radial support for the Spiral Wound components, and acts as a compression gauge to prevent the Spiral Wound component from being crushed. Normally the outer guide rings are furnished in mild steel, but can be supplied in other metal when required by operating conditions.

Style WR gaskets consist of a winding with a solid metal outer guide ring. These gaskets can be used on plain flat face flanges and on raised face flanges. The outer guide ring serves to center the gasket properly in the flange joint, acts as an anti-blowout device, provides radial support for the Spiral Wound components, and acts as a compression gauge to prevent the Spiral Wound component from being crushed. Normally the outer guide rings are furnished in mild steel, but can be supplied in other metal when required by operating conditions.

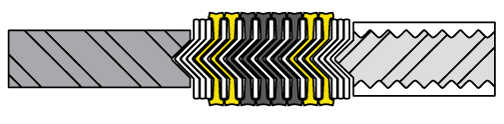

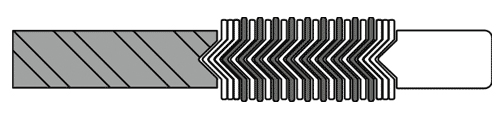

DELTAONE Style SWRI

Style WRI is identical to style WR, with the addition of an inner ring. The inner ring also serves several functions. Primarily, it provides radial support for the gasket on the I.D. to help prevent the occurrences of buckling or imploding. Its I.D. is normally sized slightly larger than the I.D. of the flange bore, minimizing turbulence in process flow. The inner rings are normally supplied in the same material as the spiral wound component. DELTAONE normally manufactures standard Style WR and WRI spiral wound gaskets to ASME B16.20, designed to suit ASME B16.5 and ASME B16.47 flanges.

Style WRI is identical to style WR, with the addition of an inner ring. The inner ring also serves several functions. Primarily, it provides radial support for the gasket on the I.D. to help prevent the occurrences of buckling or imploding. Its I.D. is normally sized slightly larger than the I.D. of the flange bore, minimizing turbulence in process flow. The inner rings are normally supplied in the same material as the spiral wound component. DELTAONE normally manufactures standard Style WR and WRI spiral wound gaskets to ASME B16.20, designed to suit ASME B16.5 and ASME B16.47 flanges.

SPECIALTY SPIRAL WOUND GASKETS

DELTAONE Inhibitor

DELTAONE Inhibitor gasket provides corrosion resistance in the most extreme conditions. It combines a HTG filler configuration with highest purity graphite, and a Kammpro inner ring laminated with soft PTFE material. The design of the Inhibitor gasket utilizes the Kammpro inner ring to provide the primary sealing interface. The inner ring material and its covering layer are inert in terms of corrosion through contact with dissimilar materials. This fire safe design incorporates the sealing integrity of highest purity graphite in conjunction with mica on the ID and OD, preventing the entrance of further corrosive conditions to the media.

DELTAONE Inhibitor gasket provides corrosion resistance in the most extreme conditions. It combines a HTG filler configuration with highest purity graphite, and a Kammpro inner ring laminated with soft PTFE material. The design of the Inhibitor gasket utilizes the Kammpro inner ring to provide the primary sealing interface. The inner ring material and its covering layer are inert in terms of corrosion through contact with dissimilar materials. This fire safe design incorporates the sealing integrity of highest purity graphite in conjunction with mica on the ID and OD, preventing the entrance of further corrosive conditions to the media.

DELTAONE Style SWRI-LC

Style WRI-LC gaskets provide a seal at relatively lower seating stress. This means that our design requires less bolt load to seat, yet still has the recovery like a standard spiral wound. The SWRI-LC gasket is typical to 150# and 300# class flanges, where users have a concern with insufficient potential of pre-load. But, the density of the SWRI-LC gasket can be varied to meet virtually any requirement. Electronic controls on DELTAONE' SpiraSeal machines assure high quality precision welding with equal spacing, the correct number of metal plies on the gasket inside periphery, proper ratio of metal to filler, proper number of metal plies on the outside and spot welds on the O.D.

Style WRI-LC gaskets provide a seal at relatively lower seating stress. This means that our design requires less bolt load to seat, yet still has the recovery like a standard spiral wound. The SWRI-LC gasket is typical to 150# and 300# class flanges, where users have a concern with insufficient potential of pre-load. But, the density of the SWRI-LC gasket can be varied to meet virtually any requirement. Electronic controls on DELTAONE' SpiraSeal machines assure high quality precision welding with equal spacing, the correct number of metal plies on the gasket inside periphery, proper ratio of metal to filler, proper number of metal plies on the outside and spot welds on the O.D.

DELTAONE Style SWRI-LP

Designed for highly corrosive environments, Style SWRI-LP is a Spiral Wound gasket with a conventional outer guide ring and a "Kammpro" style R inner ring. This dual sealing design engages the raised face completely from the O.D. to the bore. The winding can be constructed with the required metal and soft filler specified by the user. The "Kammpro" inner ring metal can be ordered in any alloy, such as Monel, or in Carbon Steel. A Carbon Steel inner ring can be given a protective PTFE coating for increased chemical resistance. The Kammpro inner ring is faced typically with either 0.020" thick EPTFE or graphite. The WRI-LP has seen wide-spread approvals for HF Acid service, although this design has much further potential. Its main advantages are: no metal contact with the media; chemical resistance; fire safe design; sizing to meet ASME B16.5; available in large diameter and special flanges.

Designed for highly corrosive environments, Style SWRI-LP is a Spiral Wound gasket with a conventional outer guide ring and a "Kammpro" style R inner ring. This dual sealing design engages the raised face completely from the O.D. to the bore. The winding can be constructed with the required metal and soft filler specified by the user. The "Kammpro" inner ring metal can be ordered in any alloy, such as Monel, or in Carbon Steel. A Carbon Steel inner ring can be given a protective PTFE coating for increased chemical resistance. The Kammpro inner ring is faced typically with either 0.020" thick EPTFE or graphite. The WRI-LP has seen wide-spread approvals for HF Acid service, although this design has much further potential. Its main advantages are: no metal contact with the media; chemical resistance; fire safe design; sizing to meet ASME B16.5; available in large diameter and special flanges.

DELTAONE Style SWRI-HTG

Style SWRI-HTG gaskets combine the corrosion and oxidation resistance of mica with the "sealability" of flexible graphite. The mica material, in conjunction with the metal spirals serves as a barrier between oxidizing process conditions and/or external air and the graphite. While Inconel X-750 is commonly selected as the winding metal, any alloy can be selected. The overall effective rating of the HTG configuration can go to a MAX of 1500°F.

Style SWRI-HTG gaskets combine the corrosion and oxidation resistance of mica with the "sealability" of flexible graphite. The mica material, in conjunction with the metal spirals serves as a barrier between oxidizing process conditions and/or external air and the graphite. While Inconel X-750 is commonly selected as the winding metal, any alloy can be selected. The overall effective rating of the HTG configuration can go to a MAX of 1500°F.

DELTAONE Style SWRI-HF

This gasket was developed for HF acid applications. It consists of a Monel and PTFE winding with a carbon steel centering ring and a PTFE inner ring. The carbon steel outer ring can be coated with special H.F. acid detecting paint if desired. The PTFE inner ring reduces corrosion to the flanges between the bore of the pipe and the I.D. of the spiral wound sealing element.

This gasket was developed for HF acid applications. It consists of a Monel and PTFE winding with a carbon steel centering ring and a PTFE inner ring. The carbon steel outer ring can be coated with special H.F. acid detecting paint if desired. The PTFE inner ring reduces corrosion to the flanges between the bore of the pipe and the I.D. of the spiral wound sealing element.

DELTAONE Style SWRI-RJ

The style WRI-RJ gasket is identical to a Style SWR in construction features but is specially sized to be used as a replacement gasket for flanges machined to accept oval or octagonal ring joint gaskets. The sealing component is located between the I.D. of the groove machined in the flange and the flange bore. These are intended to be used as replacement parts and are considered a maintenance item. In new construction, where Spiral Wound gaskets are intended to be used, raised face flanges should be utilized.

The style WRI-RJ gasket is identical to a Style SWR in construction features but is specially sized to be used as a replacement gasket for flanges machined to accept oval or octagonal ring joint gaskets. The sealing component is located between the I.D. of the groove machined in the flange and the flange bore. These are intended to be used as replacement parts and are considered a maintenance item. In new construction, where Spiral Wound gaskets are intended to be used, raised face flanges should be utilized.

POPULAR SPIRAL WOUND GASKET APPLICATIONS

DELTAONE Style SMW &SMWC

These gaskets are available in round, obround, and oval shapes and are used for standard manhole cover plates. When Spiral Wound manhole gaskets with a straight side are required, it is necessary that some curvature be allowable, given to the fact that Spiral Wound gaskets are wrapped under tension and therefore tend to buckle inward when the gaskets are removed from the winding mandrel. As a rule of thumb, the ratio of the long I.D. to the short I.D. should not exceed 3 to 1.

These gaskets are available in round, obround, and oval shapes and are used for standard manhole cover plates. When Spiral Wound manhole gaskets with a straight side are required, it is necessary that some curvature be allowable, given to the fact that Spiral Wound gaskets are wrapped under tension and therefore tend to buckle inward when the gaskets are removed from the winding mandrel. As a rule of thumb, the ratio of the long I.D. to the short I.D. should not exceed 3 to 1.

DELTAONE Style SH

Style SH gaskets are for use on boiler handhold and tubecap assemblies. They are available in round, square, rectangular, diamond, obround, oval and pear shapes. DELTAONE has tooling available for manufacturing most of the standard handhold and tubecap sizes of the various boiler manufacturers. However, these are also available in special sizes and shapes. (To order special gaskets, dimensional drawings or sample cover plates should be provided in order to assure proper fit.)

Style SH gaskets are for use on boiler handhold and tubecap assemblies. They are available in round, square, rectangular, diamond, obround, oval and pear shapes. DELTAONE has tooling available for manufacturing most of the standard handhold and tubecap sizes of the various boiler manufacturers. However, these are also available in special sizes and shapes. (To order special gaskets, dimensional drawings or sample cover plates should be provided in order to assure proper fit.)

DELTAONE Style SWP or SWRP

These gaskets are similar to Style SW and Style SWR, with the addition of pass partitions for use with shell and tube heat exchangers. Partitions are normally supplied as double-jacketed construction, made of the same material as the spiral wound component. The partition strips can be soft soldered, tack welded or silver soldered to the spiral wound component. The double-jacketed partition strips are normally slightly thinner than the spiral wound component in order to minimize the bolt loading required to properly seat the gasket.

These gaskets are similar to Style SW and Style SWR, with the addition of pass partitions for use with shell and tube heat exchangers. Partitions are normally supplied as double-jacketed construction, made of the same material as the spiral wound component. The partition strips can be soft soldered, tack welded or silver soldered to the spiral wound component. The double-jacketed partition strips are normally slightly thinner than the spiral wound component in order to minimize the bolt loading required to properly seat the gasket.

DELTAONE Style SL

The spiral wound components of Style SL are identical to those of Style SW and in addition have a wire loop welded to the outer periphery of the gasket, sized so as to fit over diametrically opposite bolts, for proper centering of the spiral wound component on the gasket seating surface. Whenever possible, it is recommended that a Style SSWR gasket be used in lieu of a Style SL gasket because of the obvious advantages of the outer solid metal gauge ring. The Style SL is considerably more difficult to produce than the Style SWR and therefore more expensive.

The spiral wound components of Style SL are identical to those of Style SW and in addition have a wire loop welded to the outer periphery of the gasket, sized so as to fit over diametrically opposite bolts, for proper centering of the spiral wound component on the gasket seating surface. Whenever possible, it is recommended that a Style SSWR gasket be used in lieu of a Style SL gasket because of the obvious advantages of the outer solid metal gauge ring. The Style SL is considerably more difficult to produce than the Style SWR and therefore more expensive.