- info@deltaone.in

- +91 98840 09696

Semi Metallic Gaskets

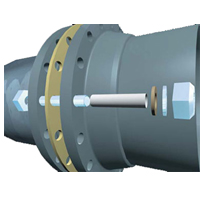

Insulation kit Gaskets

Flange Isolation/Insulation Kits; include insulating sleeves that electrically separate the bolts and the insulating washers providing electrical insulation for each bolt and nut. DELTAONE flange isolation kits are designed to provide complete electrical insulation of a flange assembly.

DELTAONE flange isolation kits are available for all flange sizes, types, pressures, and materials including, Mylar, G-10, Nomex, and Phenolic. DELTAONE sealing gaskets are available in plain phenolic, rubber faced phenolic, G-3 high-temp phenolic glass, G-7 silicone glass, G-10 epoxy glass, G-11 epoxy glass, Nitrile, EPDM, Teflon, Viton, and Special Nitrile.

DELTAONE flange isolation kits are available for all flange sizes, types, pressures, and materials including, Mylar, G-10, Nomex, and Phenolic. DELTAONE sealing gaskets are available in plain phenolic, rubber faced phenolic, G-3 high-temp phenolic glass, G-7 silicone glass, G-10 epoxy glass, G-11 epoxy glass, Nitrile, EPDM, Teflon, Viton, and Special Nitrile.

Flange Isolation Kit with Type "E" Gaskets have the same outside diameter as the flanges. Type "E" Gaskets are manufactured with precision-located bolt holes. They are easy to center and will prevent foreign material from becoming lodged between the flange faces and shorting out the flange insulation. Type "E" gaskets are available in a wide variety of materials; G-10 epoxy glass, G-11 epoxy glass, Nitrile, EPDM, Teflon, Viton, and Special Nitrile.

Flange Isolation Kits with Type "F" Gaskets are made to fit within the bolt hole circle. The outside diameter of the gasket is slightly larger than the inside diameter of the bolt hole circle. They are available in a wide variety of materials; G-10 epoxy glass, G-11 epoxy glass, Nitrile, EPDM, Teflon, Viton, and Special Nitrile.

Type "D" Gaskets are made specifically to fit into the ring groove of RTJ flanges. They are available in reinforced phenolic and other materials.

DELTAONE sealing gaskets far exceed the sealing capabilities of flat gaskets. DELTAONE sealing gaskets consist of a sealing element positioned within a groove on opposite sides of a retainer. Elastic memory characteristics of the confined sealing elements result in near zero 'm' and 'y' factors making it possible and effect to produce a positive seal without significant bolt loads that are required to crush flat gaskets into a configuration capable of producing a marginal seal, at best.

DELTAONE sealing gaskets far exceed the sealing capabilities of flat gaskets. DELTAONE sealing gaskets consist of a sealing element positioned within a groove on opposite sides of a retainer. Elastic memory characteristics of the confined sealing elements result in near zero 'm' and 'y' factors making it possible and effect to produce a positive seal without significant bolt loads that are required to crush flat gaskets into a configuration capable of producing a marginal seal, at best.

Y = Compressive load necessary to effect a seal.

Y = Compressive load necessary to effect a seal.

M = Extra load (above Y factor) necessary to hold fluid pressure over the operational pressure range of the system. Near zero m and y factor sealing gaskets can be used to effectively seal mating surfaces made from glass, plastics, ceramics and other materials that would tend to shatter when over compressed. When used with flanged piping systems, lower bolt torques and lighter weight, lower pressure rated flanges may be used, resulting in additional material and installation savings.

- Lower bolt torques required to effect a seal

- Reduction in installation time and the need for impact wrenches or cheater bars

- Eliminates the need for retightening due to flat gasket cold flow

- Reduces the need for high tensile strength bolts or studs

- Permits the use of lighter weight or lower ANSI rated flanges

- Assures a positive seal first time, every time while eliminating costly delays to tighten leaking flanges during initial pressurization

- Pressure energized, controlled confinement of DELTAONE sealing elements

- Sealing elements maintain contact with mating surfaces even though the surfaces may tend to warp or separate due to thermal shock, pressure fluctuations or other external forces

- Internal fluid pressure forces the seal elements against the mating surfaces increasing the effectiveness of the seals.